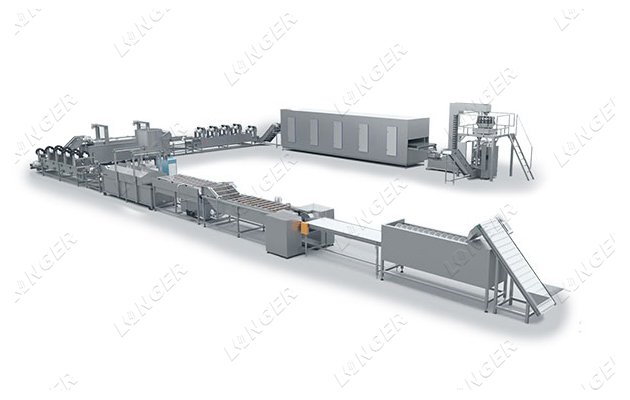

Sweet Potato Chips Production Line Introduction:

The sweet potato chips production line is very suitable for the mass production of food processing plants, restaurants and other large and medium-sized enterprises.The production capacity of the production line is between 200kg/h-1000kg/h, and there are three heating methods (electricity, coal, gas) to choose from.

How To Make Fried Sweet Potato Chips:

Cassava-lifting-Washing And Peeling- Selection- Lifting- Cutting Machine-Rinsing-Blanching-Vibration Dehydration - Frying - De-oiling -Seasoning-Packing

Lifting: Lifting the cassava to the place of cleaning.

Washing And Peeling: Use a brush washing machine to clean the cassava skin.

Selection: This sweet potato process is mainly to select and remove unqualified sweet potato fries.

Lifting: Lifting the cassava to the cutting machine.

Cutting: Use a cutting machine to cut the cassava into chips. The size of the cassava can be adjusted.

Rinse: Wash the cut sweet potato chips to remove the starch on the surface.

Blanching Blanching Sweet Potatoes: Blanching can not only kill the bacteria and molds on the surface of the sweet potato, but also inhibit the effect of mold, prevent the sweet potato from oxidizing, and play a role in color protection.

Dehydration: Use a vibration dehydrator to remove water from the surface of the sweet potato

Sweet Potato Fry Maker: The dehydrated sweet potato chips are fried in frying machine. The frying temperature and time can be adjusted according to different materials to ensure that the fried sweet potato chips are beautiful in color, crisp and delicious.

De-oiling: After frying, the sweet potato chips need to be de-oiled in a degreasing machine to remove excess oil.

Seasoning: The fried sweet potato chips can be adjusted into different flavors to meet customer needs.

Packaging: Multi-head weighing machine is used for weighing and packaging, which is convenient for sale.

Advantages Of Sweet Potato Chips Production Line:

*As a professional solution provider, we have our own factory and professional technicians, and we can provide professional solutions according to customer needs.

*Most of our production lines are made of 304 stainless steel, which is durable and meets food hygiene standards.

*We have professional after-sales service personnel who can help customers solve the difficulties they encounter