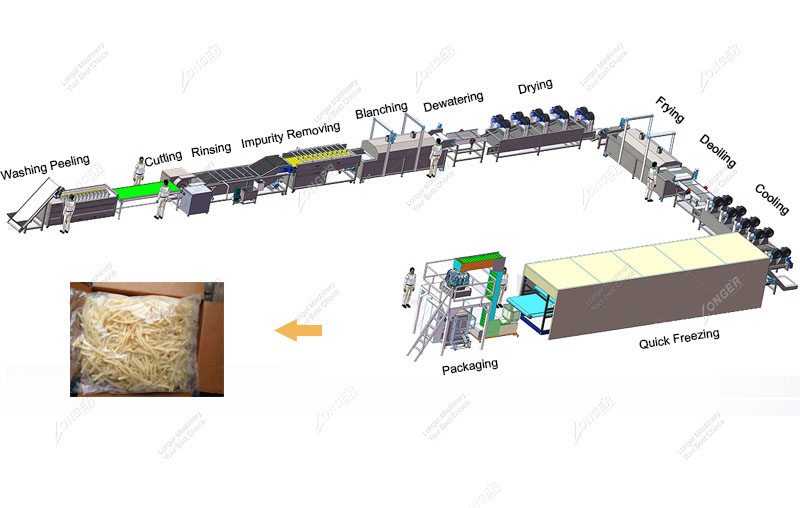

This French fries processing plant can produce 250-500 kg/h French fries according to special requirement. French fries processing steps: potato cleaning and peeling - cutting - rinsing - blanching - shaking drain - frying - deoiling - mixing - freezing - weighing packaging.

Frozen French Fries Processing Plant

- Potato peeling: Fresh potatoes are first cleaned and peeled by potato peeler machine.

- Potato cutting: The peeled potatoes are cut into potato strips by a high-speed potato cutting machine.

- Potato strips rinsing: The cut French fries into the ozone disinfection washing machine, rinse the surface mucus of potato strips.

- French fries blanching: Clean fries into the blanching machine for blanching, in order to passivate the oxidase in the French fries, prevent deterioration of color, speed up teh water removing.

- Vibrating water removing: After blanching, the French fries into the vibration dewatering machine to remove excess water.

- French fries frying: The French fries after removing water are sent to the French fries fryer for frying treatment by the lifting conveyor.

- Air drying oil removing: The fried fries are drained after being air-dried and then fed into a seasoning machine.

- Mixing: The flavoring machine has a dip-type seasoning roller, which fully controls the speed of rotation and the material. It is equipped with an automatic powder feeding device that can adjust the size of the powder to be fed and fully mix the fries and seasoning powder.

- Weighing and Packaging: The fries are sent to the packaging machine for vacuum packaging or ordinary packaging. If necessary, a weighing mechanism can be added.

| Model | LG-250 |

| Customization | Yes |

| Catogary | French Fries Machine |

| Voltage | 380v |

| Power | 250kw |

| Application | Processing French Fries |

| Packing | Customer Requirement |

| Application | Snack food factory, frozen food factory, fruit and vegetable processing plant, seasoning processing equipment, etc. |

| After-sale Service | One year warranty |

1, How much is the machine cost? Answer: Different models have different price, just tell us your requirement, our sale will suggest you suitable model and price. 2, What is the raw material of your machine? Answer: Our machines are made of stainless steel material, if you have special requirement for the machine, just feel free to tell us. 3, What if the voltage can't fit our country? Answer: The voltage can be customized, just tell us before the machine is made. 4, For the frying machine, which heating way is better? Answer: Dear, we have gas heating and electric heating, also can be customized. You can choose the suitable one according to your need.