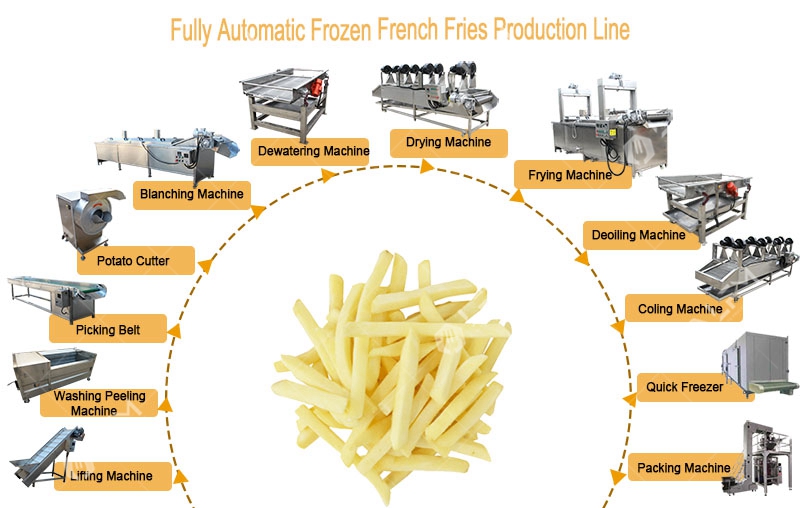

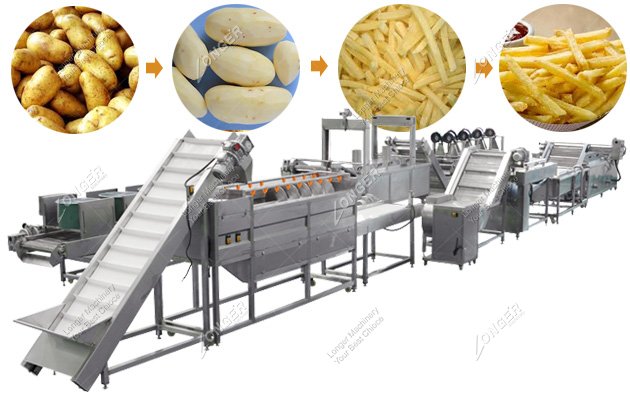

Our factory supply frozen french fries line with different production capacity, from 150 kg/h-3000 kg/h. And automaitc french fries production line includes machines for potato washing and cleaning, potato peeling, cutting, rinsing, blanching, drying, frying, deoiling, IQF freezing, and packing. And this production machines may need adjust based on different production requirement.

When start French fries business, learn French fries manufacturing plant cost first. For only machine cost, price ranges from $20000 to $500000, different parameter will cost different price. Whole French fries production line business will include unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower requirements, packaging and shipping requirements, etc. Here will intorduce french fries production line in details.

Frozen French Fries Manufacturing Process

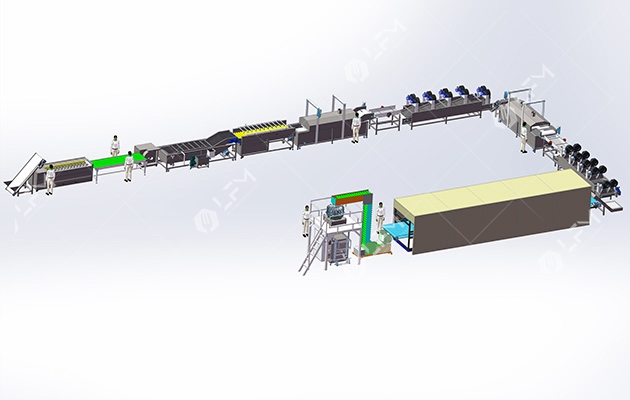

The labor cost in modern society is high. The manual way to make French fries take a lot of workers and hours to process the raw material which is not only costly and ineffectively. We provide a fully automatic French fries production line to save more labor costs for customers, thereby helping customers create more benefits. We provide french fries project solution according your detail requirement. And, our team can provide factory for you freely.

Automatic Frozen French Fries Production Line Manufacturing Video

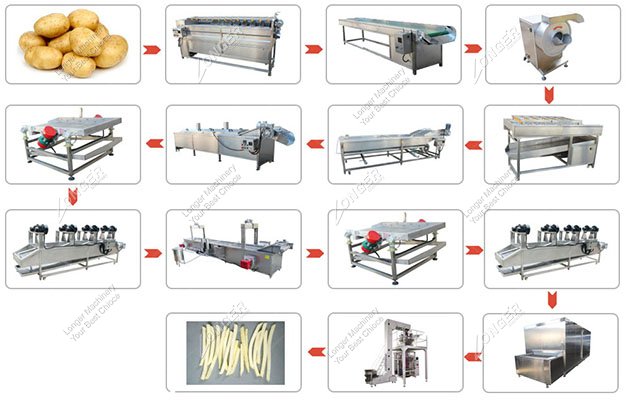

- Washing and peeling: The potatoes are first washed and peeled by a washing and peeling machine to remove dirt and unnecessary parts on the surface of the potatoes.

- Cutting: The washed potatoes are cut into strips by a high-speed French fry cutter to form the initial shape of the French fries.

- Rinsing: The cut French fries enter the rinsing machine and the mucus on the surface is rinsed clean using an vegetable washing machine.

- Blanching: The rinsed French fries enter the blanching machine for blanching to passivate the oxidase in the French fries, prevent color deterioration, and accelerate dehydration.

- Vibration dewatering: The blanched French fries enter the vibration drying machine to remove excess water.

- Frying: The French fries with excess water removed are sent to the fryer for frying through a lifting conveyor.

- Draining oil: The fried French fries are drained by an air drying lifter and then sent to the mixer for seasoning.

- Mixing: The mixer has an angled seasoning drum, which automatically controls the speed and material capacity. It is equipped with an automatic powder feeding device, which can adjust the amount of powder fed to fully mix the French fries and seasoning powder.

- Weighing and packaging: The seasoned French fries are sent to the packaging machine through a lifting conveyor belt for vacuum packaging or ordinary packaging. A weighing mechanism can be added as needed. In addition, the production of quick-frozen French fries also includes the steps of quick freezing and fully automatic packaging:

- Quick freezing: The quick freezer makes the center temperature of the French fries reach -18°C in a short time, and passes through an ice crystal production belt (0 to -5 degrees) to reduce the loss of nutrients and maintain the original flavor.

- Fully automatic packaging: The fully automatic packaging machine can automatically complete feeding, bag making, filling, bag making, date printing, counting and finished product output, which greatly saves manpower and material resources and improves production efficiency.

| No. | Equipment List | Size(mm) | Power(kw) |

| 1 | Lifting Machine | 2400*1100*1600mm | 0.75 |

| 2 | Potato Washer Peeler | 3200*850*1400mm | 4.37 |

| 3 | Picking Belt | 3500*1100*900mm | 0.75 |

| 4 | Potato Cutting Machine | 950*800*950mm | 1.1 |

| 5 | Impurity Removal | 2600*1300*1100mm | 2.2 |

| 6 | Rinsing Machine | 4000*1400*1300mm | 6.6 |

| 7 | Blaching Machine | 5000*1200*1300mm | 120 |

| 8 | Vibrating Dewtering Machine | 1800*1230*1020mm | 0.5 |

| 9 | Drying Machine | 4000*1200*1600mm | 7.5 |

| 10 | Lifting Machine | 2000*1100*1300mm | 0.75 |

| 11 | Frying Machine | 5000*1400*2200mm | 180 |

| 12 | Vibrating Deoiling Machine | 1800*1230*1020mm | 0.5 |

| 13 | Drying Machine | 4000*1200*1600mm | 7.5 |

1, How much is the machine cost? Answer: Different models have different price, just tell us your requirement, our sale will suggest you suitable model and price. 2, What is the raw material of your machine? Answer: Our machines are made of stainless steel material, if you have special requirement for the machine, just feel free to tell us. 3, What if the voltage can't fit our country? Answer: The voltage can be customized, just tell us before the machine is made. 4, For the frying machine, which heating way is better? Answer: Dear, we have gas heating and electric heating, also can be customized. You can choose the suitable one according to your need.